Interview with Berto Industria Tessile: Innovation, Quality and Efficiency

Have you ever heard of companies that produce sustainably without even realizing it? Flavio Berto, CEO of Berto Industria Tessile, talks about his textile industry that makes sustainability a philosophy, a competitive strategy, and not exclusively a marketing lever for its own sake.

Berto Industria Tessile was born in 1887 in Bovolenta and the link with the territory is very strong: there is all the Berto production. Despite the long tradition, the industry has never stopped innovating and adapting promptly to market changes.

S: Mr. Berto, would you like to tell us what is the history of your textile industry and what are the sectors in which you have worked over the years?

F: We were born in 1887 and I am part of the fourth generation.

It all comes from the proximity to a river that connects us to Chioggia, where my great-great-grandfather started making sails for boats.

The business began as a shop, to move on to the production of frames from which the sails are born. During the war period, we moved to home textile packaging and after the war, we entered the world of clothing due to the strong demands.

This is how we entered the world of fashion: we started from work fabric (a lot of shirts) and then, in the 60s, we started the first indigo line to make blue jeans fabric (at the time it was the material for work clothes), which then became fashion and we continued to develop it following the market.

The packaging business part has split and is currently being followed by my sister.

It all started following the needs and opportunities that opened up in the market. I speak in the plural but in reality, the biggest choices were still made by my grandparents and my father.

I followed denim, moving it to a higher range of customers (we serve brands that make pants from 100 euros upwards). Being a 100% Italian production, we have costs that do not allow us to go under a certain type of market.

S: How has the Berto industry been able to maintain over the years a reputation for reliability and quality linked to tradition and, at the same time, to always keep up with market demand and tastes? What does it mean to you to innovate?

F: Innovation I see it divided into two parts: I see “external” innovation in the final product, that is, trying to follow market needs or stimulate change (as an industry, being Italian and being expensive, we are asked for added value, hence innovation). Then there is internal innovation: for us, it means constant work down to the smallest detail to make production more efficient according to the customer’s needs (best possible service in terms of price, sustainability).

Sustainability in terms of innovation is a concept that we carry with us because, returning to the concept of an expensive Italian company, we are born with a historical concept of “less I buy, less consumption, less cost”. So everything we buy, everything we have to use to make a fabric, we always try to use it in the best possible way by reducing waste or in any case reusing them in other processes.

S: Is sustainability therefore also linked to a reduction in costs?

F: Absolutely yes! Indeed, we have been doing sustainability for 20 years without realizing it. Berto is located between the Euganean Hills Natural Park and the Venice Lagoon, which is another natural park. We are targeted on an environmental level! We do not have regional infrastructures, so we have to purify the water, take it from the river and when we have to re-introduce it into the river, we have extremely strict water analysis parameters.

We realized that between dirtying something and then cleaning it, it costs less to avoid using it!

S: This concept is not so obvious, both in the fashion industry and in any other sector. Usually, we talk more about treatment rather than prevention, right?

F: Yes and it is a very topical topic. I read last week that the flu, with Covid, has dropped. Paradoxically today, with masks and disinfectants, the flu has been eradicated. Until the day before yesterday, one person went out, was sick and infected other people. This shows that prevention makes problems disappear, and it is the same at a company level: if you use something and do it best by reusing it as many times as possible, trying to eliminate waste, you take away the problems downstream on how to clean up the same waste.

It is not easy, you have to work on it, but in Italy, it is the only system we have found to be competitive.

S: Speaking of costs, is Made in Italy an advantage or a limit?

F: The first question to ask is what Made in Italy is. If Made in Italy is an end in itself, it is not an advantage: taking a suit and “attaching the tricolor” doing it badly, is not what the market wants. The market does not buy because an object is Made in Italy but because behind it there is taste, craftsmanship, or something well done. If there is something well done and we put the Made in Italy recognition on it, then that becomes an added value.

If both conditions are met, we are competitive.

For example, Ferrari is not the first simply because it is Made in Italy, it is because it is one of the best cars in the world, this is the true value.

The biggest competitors of the Italians (removing the price part) are the Japanese: a culture where everything is done with attention to detail, creating unique products. The Italian must compete in that area, not where there is a price/quality ratio because it would be useless and we would never be able to be competitive.

S: We can affirm that your way of producing sustainably is for you a source of competitiveness, not only in terms of cost but also in terms of response to demand. Do you see a positive trend from this point of view?

F: Sustainability is a fundamental condition for being competitive. In reality, we never realized that it was also a marketing lever and it was one of the big problems we had in the company. A luxury customer encouraged us to communicate our work and, indeed, we realized that continuing to operate on the search not to dirty, recycle, reuse, reduce consumption was something that the market was looking and researching. I do not know if it is a real lever of competitiveness because now there is a great deal of attention to sustainability within the professionals, but I do not know how much you pay at the level of the final customer.

In any retail, it is difficult to find a garment on which “sustainable” is written on it, it is a wave that will arrive in the coming months and in a very strong way because it is talked about in all sectors.

S: Working with many brands, what we are seeing is that sustainability is increasingly a request from major buyers (eg: Zalando). So it’s almost a necessary condition, don’t you think so?

F: I agree. What I mean is that few still know where to buy sustainable clothes. Paradoxically, those who claim to use organic materials absurdly are companies that have nothing sustainable. When these conditions that buyers are placing on the market (fortunately), I am curious to know if it will be a lever that will change people’s consumption model. We don’t know this yet, though, because it’s a game that started like a Tsunami, particularly this last year.

S: The 2020 statistics tell us that there has been greater attention from consumers from this point of view, there is also greater attention to the values of the company they bought from. If this is the trend, we will see some feedback, even if in Italy we are still at the beginning of the journey.Considering the innovations you have made at the fabric level, would you like to tell us about your “pianeta” fabric?

F: We have been facing sustainability for some years now. The first step was to use sustainable raw materials (no chemicals, pesticides, raw materials such as organic cotton, etc.). We realized, however, that if I take organic cotton I have to double the number of fields and pull down trees and it’s not so sustainable. So I move towards synthetic fibers which are made with petroleum and therefore not sustainable. In the end, I can produce in the most sustainable way possible but in the end, I throw it away, filling the world with waste.

We wondered how to recover waste, creating items created from recycled cotton from our productions. We have found a solution with an Italian company (Marchi & Fildi): we process the scraps to make them yarn again.

We have therefore created this line of products with a high percentage of recycled cotton (up to 70%) mixed with natural fibers, so it is cotton: one part recycled and one part new. At the moment we are among the only ones in the world that reach certain percentages. Furthermore, our Pianeta fabrics are all GRS certified (which certifies those products sustainably made from the recycled product for at least 50%).

S: How was the feedback on the recycling market compared to organic?

F: Still slow. There are the first brands that start looking at it with interest. The first sustainability boom was “we want natural raw materials”, so now, you can also see it in the fashion shows, there are fabrics made from organic cotton, from natural fibers such as Tencel, linen, hemp, etc. environmentally sustainable materials. Now there are the first brands that are wondering where to throw the waste and start looking at the recycled. It is progressing slowly but it is a very appealing project that is coming to life now. As always, we left a little too early! We have this bad habit of starting too early on the market …

S: In terms of quality, however, are there any differences? Because this is one of the obstacles for recyclers, that of performance.

F: In terms of performance it is practically the same as the normal fabric.In terms of comfort, it is the same, in terms of image it is very similar.

We can’t have as wide a range of yarns as regular yarn (the only difference). The “flames” effect we use, which gives the effect to the trousers, we are unable to replicate it as we would like so we are a bit tied only from this point of view. As for the performance of elasticity and durability, it is the same as the normal fabric.

S: You are among the companies that have signed the Detox commitment of Greenpeace and benefit from certifications such as GOTS. What kinds of benefits can initiatives like these bring?

F: It’s a must. Let’s go back to the concept of before the buyers. We started first to have these certifications and agreements and now they are paying us back, in the sense that we must not “rush” to do them.

It is not bringing me a plus in terms of the offer but it brings it as credibility and image of the company. Any brand that approaches us and sees that we are a Detox agreement company, that the whole process is approved by GOTS and GRS, is a good business card that gives credibility. This is the added value it is bringing us.

S: There are many innovations within your processes, starting with water purification or your frames. Are there any other innovations you’d like to talk about?

F: We have a lot of them. The focus currently is on the use of these raw materials, then consciously using water and emissions into the atmosphere. Therefore the three big projects currently in progress are: understanding how to dye in the finishing phase by reducing the use of water by 50% -60%, then trying to dye only with colors, without washing (we are doing it with particular oxidations with innovative machinery).

We are doing the same thing with indigo using machinery that should reduce the length of the machine by up to 50%; to dye a pair of indigo trousers, we must pass it on a machine that has a draw-in of 600 m. We are making this 600m to 200m, it is a very complex process. What has been said so far is therefore at the product level: understanding how to reduce the use of water and chemicals to dye fabrics and yarns.

The other process currently underway is to understand how to use the exhaust gases that we risk throwing into the environment to clean the wastewater we have, then how to use the boilers to avoid the emission of co2 to purify the water. This allows us to increase the water we are going to reuse. To date, we reuse 60% of the water. The part that we are going to download in the channel, however, comes out with values that comply with the standards. To do this process we have to use chemicals but we try to eliminate the smoke from the boilers. We should gradually become a zero-consumption company.

S: You have many initiatives that involve the theme of sustainability at 360 degrees! Your analytical approach to impact analysis is also noteworthy. I think it is a fundamental approach because talking about percentages has a greater effect and allows you to highlight areas for improvement and have a more targeted approach. So you have a scientific approach to what the choice of how to reduce the impact is, right?

F: Well yes! In the end, the company has to do a cost-benefit analysis, especially when you have so many ideas. To be able to realize what you are doing you have to work analytically. Many companies see the sustainable aspect like marketing, for us, it is efficiency, which is why we have never carried the sustainability flag so high, we didn’t even realize it. Now it is fashionable to be sustainable: I read a few weeks ago about a company in the Far East that said “we are sustainable” with a photo of the roof with photovoltaic panels … is that sustainable? I do not think so. I think sustainability is about consuming less, saving money, using products more efficiently, and making the most of the outputs you have to throw away. To do this, however, you have to work with numbers in hand.

S: A question about the traceability of the supply chain: cotton is currently in the spotlight for the US which has blocked cotton imports from China for the Xinjiang theme. Is it possible today to have a traced cotton supply chain?

F: Theoretically yes. You have to see what and how much you want to track; some things make sense to me, other tracking systems are exasperated.

In the American case, other countries do what China does. One should understand why to target only one side. Then you can also trace the process but then you have to understand what is behind every single action.

For example, to maintain traceability we have made a choice of km0 that is turning against us, absurdly. Our cotton comes from Greece or Spain and are not organic. So I ask myself: is organic cotton made in Pakistan better (it does a lot but it is much more complex to trace for manual harvesting) or is Greek cotton better with capillary irrigation, a crop that uses less land? The organic is used because it is traceable and therefore better, but it is necessary to understand how traceability is done. At this moment, for me, there is so much confusion because there is an industrial quantity of organs that make traceability; one that says everything would be enough because when there is too much proposal you no longer know who to believe. When there is a lot of supply and little demand, you almost put demand into crisis.

S: So for you, the solution is a short supply chain?

F: Yes. I don’t get that far, I don’t physically go to see the garments where they grow my cotton. Not being able to get to this level of sophistication, I go to countries where I am safe because certain regulations work as well as countries that work as I want and that respect my values.

Berto’s is a fascinating case study of Italian entrepreneurship that demonstrates that converting one’s production into sustainable terms does not require sacrifices, quite the opposite!

Flavio Berto argues that sustainability becomes a necessary condition for “doing business” because it allows for cost and production efficiency: it is good for the company, good for customers, and good for the environment.

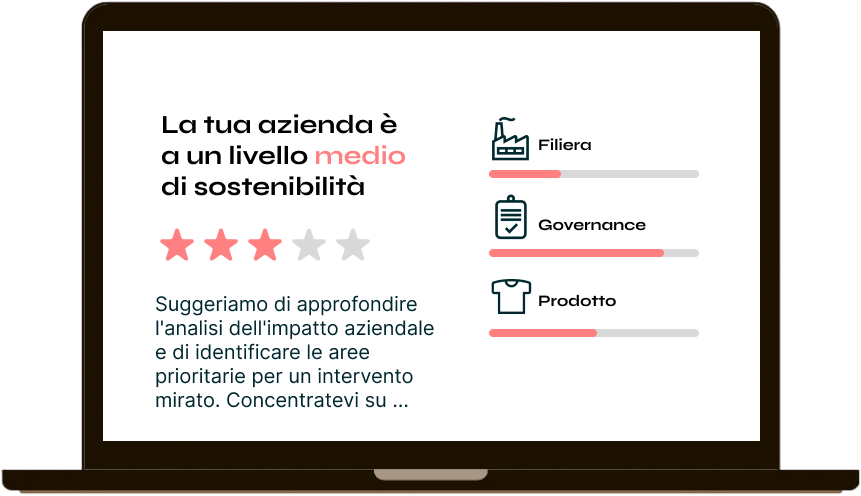

And you? Do you want to know how your company can save costs by carrying out sustainable production?

CONTACT US!

Get articles like this and the latest updates on sustainable fashion automatically!